In this in-depth interview, we delve into the advantages and unique features of the technologically advanced Q-SPD surface drive system, along with its compatibility with the powertrain design of MAKAI, in discussion with Leigh Michau, the founder of Q-SPD.

About Q-SPD Q-SPD is the designer and manufacturer of technologically advanced surface drive systems. Headquartered in New Zealand, the company has developed a unique surface drive design that offers better fuel efficiency, lighter weight, and corrosion-resistant features. With components made of epoxy composite, the system requires minimal maintenance while providing increased speed and range. MAKAI chose the Q-SPD design over more complex metallic surface drive systems, considering the significant advantages in terms of maintenance and durability.

With several M37 surface drives currently on order, we seized the opportunity to discuss in detail the design and advantages of Q-SPD drives and the history of Q-SPD with Leigh

I am Leigh Michau, the owner and designer of Q-SPD surface drives. I reside in New Zealand, where my company is also based. Being a born and raised New Zealander, I have been involved in the production of boat drives for 27 years.

Thoughts on MAKAI M37 Design:

When examining the design of the MAKAI M37, we noticed that our customers prioritize not only fuel economy and boat speed but also the ease of maintenance. Therefore, we wanted to learn more about Leigh’s expertise in surface drives and why they could be a great option for our customers. So, before delving into technical details, could you please provide more information about your expertise and experience in the field?

Certainly, as I mentioned, I am a New Zealander, born and raised in this environment. I have been passionate about boats for most of my life. I learned about surface drive technology approximately 28 years ago. I worked on surface drive projects with some other individuals for a while. However, later on, I decided that I wanted to start my own business. Consequently, effectively, I have spent the last 20 years working with surface drives. Throughout this time, my interest in this field has never waned. And undoubtedly, we will further discuss the interest generated by the topics we are going to talk about today.

What is the Main Difference of Q-SPD Surface Drives? What is the Biggest Advantage of Choosing Q-SPD Surface Drives? Of course, the biggest difference is that it is made of composite material. So, this obviously makes it lighter and reduces maintenance, but that’s not all. Beyond that, it’s supposed to be a low-maintenance and user-friendly product. Because we didn’t want to have difficulties getting on the boat and operating it. It had to be a user-friendly product, that was one aspect. So we did a lot of experiments to create a system where the operator didn’t have to adjust the rudder or anything like that to operate the drive and meet his needs. The result was a very easy to use fixed system that worked every time. And it basically always works, it should work every time! Surface drives have their own unique characteristics and there are many aspects that are different from other propellers, such as the propellers and their relationship with the boat and the water. All of these must be taken into account.

How Do Q-SPD Surface Drives Differ from a Spindle Drive System? A straight shaft drive system? It’s similar in many ways because we’re still using a straight shaft, we’re using a cut bearing like a spindle drive system. We have floating rudder bearings that are water lubricated, this is often used in the same way as a standard straight shaft propulsion system, so you can start to understand where that durability comes from. The difference comes in the propeller and how the propellers work and where they are placed. When you place a surface-cutting propeller higher up in the water, the weight of the other hardware suspended in the water is reduced and the drag is also less. And we’ve gone even further, of course it’s not that easy to pack something like this and tow it behind a boat. So you need a structure to hold everything together, which of course includes a purpose-built enclosure structure. Then we have to consider that surface propellers work in a ventilated environment, not a cavity environment compared to a normal propeller, so the requirements for this propeller are different. These differences include issues such as where it lives, how it lives and how it behaves.

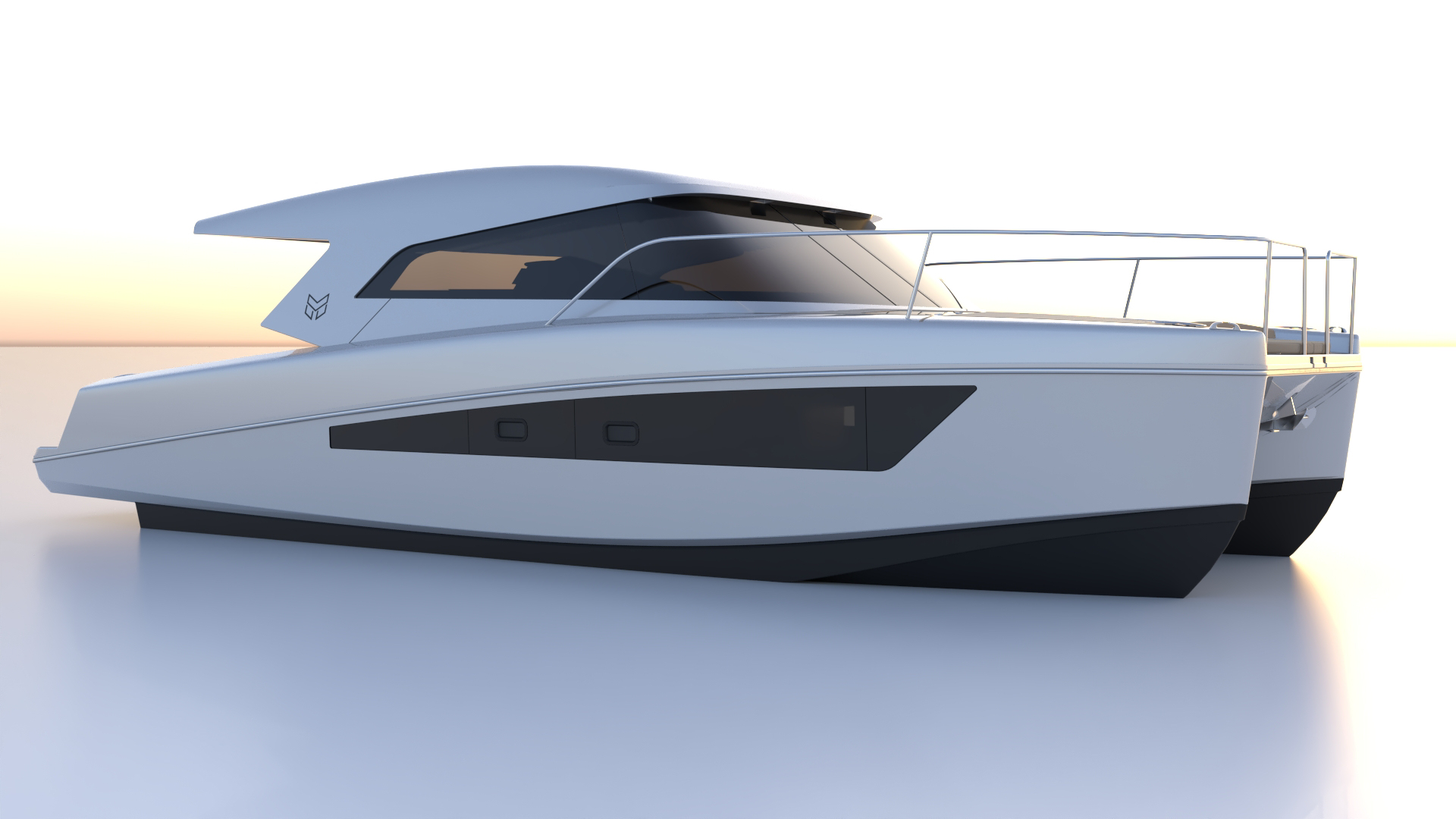

In what ways would you rate the Makai M37? When I looked at the design, I thought it was really interesting. What I really like about the boat itself is how open and fresh it feels, and you have a gorgeous open friendly space throughout the whole space. And it’s not pretentious at all. It’s a nice looking, sporty boat that goes straight ahead, that impressed me. Of course, it impresses everybody. From the presentations given to me by Shane about the boat I could immediately understand that the whole design was built on maximizing efficiency and using the best opportunities. Yes, that makes sense, absolutely.

In summary, can you explain why you use MAKAI 37 with Q-SPD Surface Drives? Absolutely. MAKAI’s design concept is all about building a more efficient body. If you are going to make a whole body more efficient, why not find the most efficient way to push it? Yes, that is a logical and logical step.

What are the Advantages of Equipping the M37 with Q-SPD Surface Drives? M37 owners can expect lower maintenance and greater performance if they choose Q-SPD surface drives rather than standard marine propulsion. Of course, speaking in a completely neutral way, it requires considerably less maintenance. Anyone who has owned a marine drive for some time will know that there is a cost to marine drive maintenance every year. Of course, it varies depending on frequency of use and state of preservation. But Q-SPDs are more forgiving in this regard.