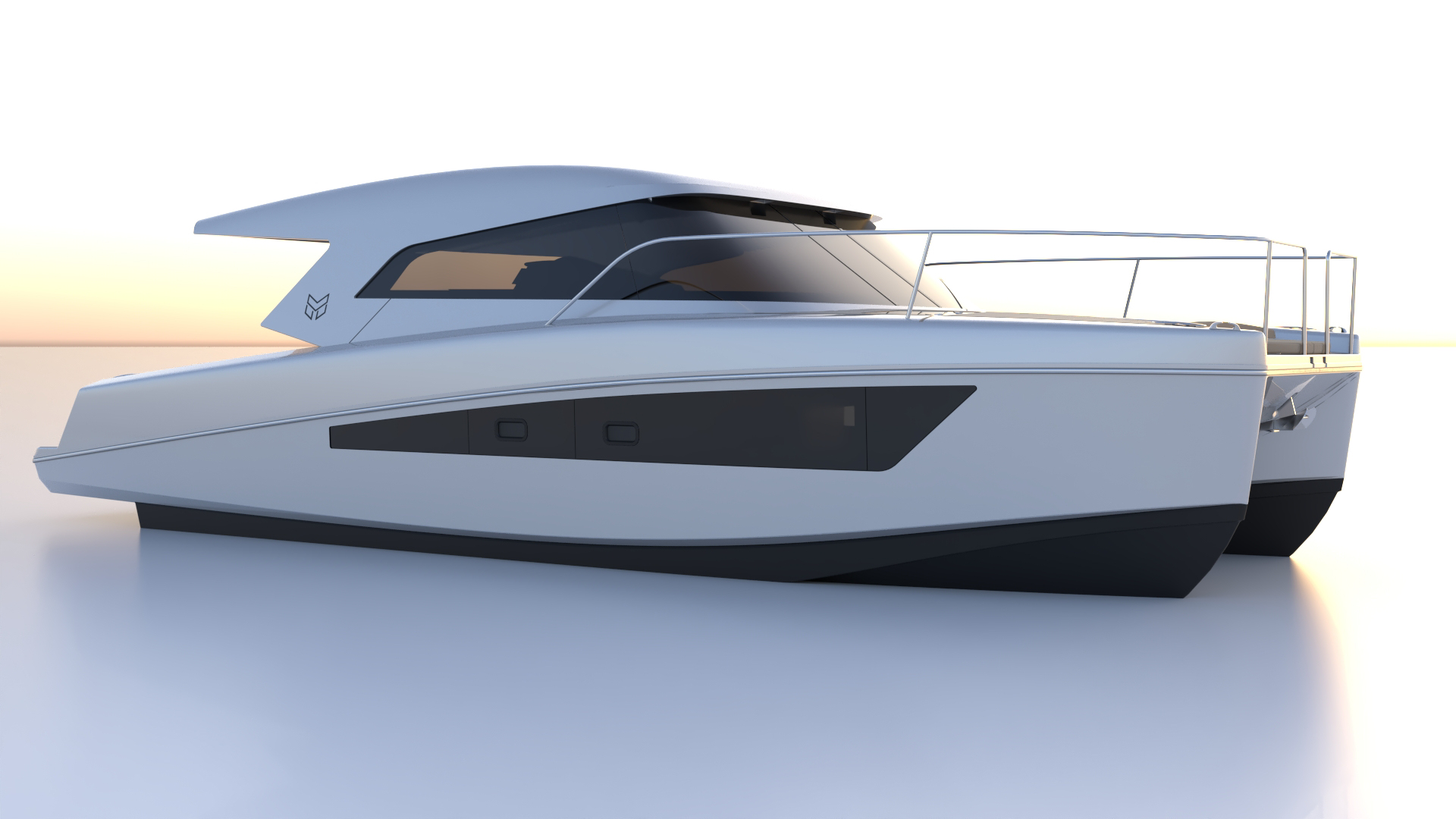

Welcome to an exciting chapter in the journey of MAKAI Power Catamarans. This week marks the completion of assembly and the start of the phase-out. We are happy to see that the production teams in our lamination factory are starting to make progress on our monthly production plans. From pushing the boundaries of structural integrity to ensuring that every detail reflects quality, join us in exploring the meticulous process and experience the MAKAI difference.

Completing the assembly means a few things to us; we have completed the engine and tank assembly, flattened the hull and set the waterline, we have also installed most of the peripheral engine equipment such as steering, hydraulics, ventilation, plumbing and sound deadening. Much of this assembly work was accomplished with the ease that comes from the flat floor built into our engine cage formwork. This will ensure that drainage water is kept away from your feet, of course protecting electronics and other sensitive equipment, as well as providing easy access and a level floor around the engine area.

We have also installed our drainage plumbing, pre-wired our electrical harnesses, installed our furniture module and completed all the necessary secondary connections and glass taping. Many manufacturers are known for skipping this step in favor of speed of production, but at MAKAI, the initial development and start of construction may have taken much longer than we originally planned, but we never compromise on quality or structural integrity. Because we believe that every boat built must first and foremost meet the strict quality standards we set ourselves.

Unlike most power catamarans built today, MAKAI took a holistic approach to the structural integrity of the M37 from an engineering perspective.

Using finite element analysis, our designers were able to determine all the potential forces the hulls would withstand. Rather than simply building this structure into additional volume bulkheads, stringers or other reinforcements, we have increased the structural integrity of this power catamaran in a revolutionary way by designing the interior as a monoblock. This design makes a significant contribution to the rigidity and structural integrity of the vessel. Due to the high cost and precision of assembly, this technology has been used by some manufacturers in a similar, albeit rare, way. However, what really takes it to the next level is MAKAI’s ‘ONE PIECE PRODUCTION’ approach. The entire internal structure is produced from a mold using vacuum infusion technology. This produces a much stronger structure than could be achieved if produced in a single piece. When this structure is bonded to the body, the result is an extremely rigid and lightweight interior, free from the creaks and creaks of typical plywood interiors.

We also added both vertical and horizontal impact baffles to the bows and designed our swim platform to be structurally isolated from the rest of the hull, adding collision protection to prevent water ingress in the event of a frontal collision or damage from the stern.

After passing through the assembly phase, our team moved on to the fit-out phase, starting with the installation of the air conditioning systems, electrical installations and hard top installation. More about this in our next update…